Surface Preparation

Diamond grinding to create proper profile. We repair cracks, joints, and imperfections to ensure a solid foundation.

Concrete Shield Coatings Inc. installs high-performance quartz broadcast floor coating systems that deliver superior slip resistance, durability, and chemical protection for demanding commercial and industrial environments.

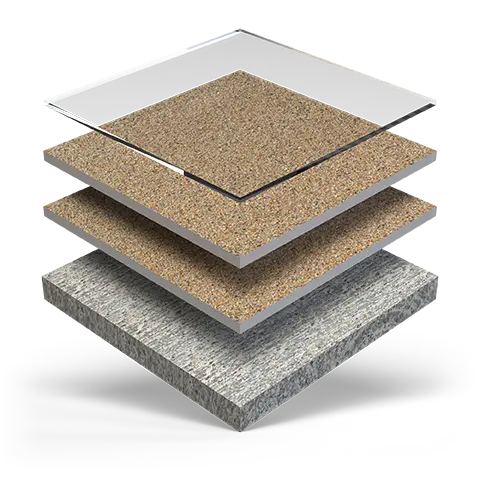

Quartz broadcast flooring is a seamless, multi-layer coating system that combines colored quartz aggregates with high-performance epoxy or polyaspartic resins.

Unlike standard epoxy or painted concrete, quartz broadcast systems offer:

Why commercial and industrial facilities choose quartz broadcast.

Textured quartz surface increases traction, reducing slip-and-fall accidents in wet environments like kitchens, pool decks, and locker rooms.

Double broadcast systems withstand heavy foot traffic, dropped tools, rolling carts, and equipment without showing wear.

Holds up to harsh cleaning chemicals, degreasers, oils, and other substances common in commercial settings.

Seamless surface with no grout lines means no place for dirt, bacteria, or mold to hide. Simply sweep, mop, or hose down.

UV-stable aggregates and topcoats maintain color without yellowing, even with outdoor exposure.

Quartz broadcast excels in environments demanding slip resistance, durability, and sanitary conditions.

Restaurants, cafeterias, and food prep areas where slip resistance and sanitation are critical.

Athletic facilities and school locker rooms with wet conditions and high traffic.

Hospitals, clinics, and labs requiring seamless, easy-to-sanitize flooring.

Animal hospitals needing chemical-resistant, easy-clean surfaces.

Production floors and warehouses with heavy equipment and foot traffic.

Production areas requiring chemical and temperature tolerance.

Service bays exposed to oils and chemicals. See also: Garage Floors

Slip-resistant flooring for beauty facilities. Learn more: Salon & Spa Floors

Professional quartz broadcast installation requires careful preparation and precise technique. Here's what to expect.

Diamond grinding to create proper profile. We repair cracks, joints, and imperfections to ensure a solid foundation.

Apply penetrating primer to seal the substrate and ensure optimal adhesion for the coating system.

Apply base coat and broadcast quartz aggregates to saturation. Allow to cure before proceeding.

For double broadcast systems: apply grout coat and second layer of quartz to rejection for maximum durability.

Apply clear or pigmented topcoat for protection and desired sheen. Final cure before returning space to service.

How quartz broadcast compares to other floor coating options for commercial applications.

| Feature | Solid Epoxy | Flake Epoxy | Quartz Broadcast |

|---|---|---|---|

| Slip Resistance | Low-Medium | Medium | High |

| Impact Resistance | Medium | Medium-High | Excellent |

| Chemical Resistance | Good | Good | Excellent |

| System Thickness | ~10-20 mils | ~40-60 mils | ~1/8" (125+ mils) |

| Best For | Light commercial | Garages, basements | Heavy commercial/industrial |

| Typical Lifespan | 5-10 years | 10-15 years | 15-20+ years |

Common questions about quartz broadcast floor coatings, installation, and maintenance.

A quartz broadcast floor coating is a seamless flooring system where colored quartz aggregates are broadcast into wet epoxy or polyaspartic resin, then sealed with a clear topcoat. This creates a highly durable, slip-resistant surface.

Professional quartz broadcast flooring typically ranges from $8 to $15 per square foot installed. Cost depends on concrete condition, single vs. double broadcast system, and total square footage. Check our service areas page.

A typical double broadcast quartz installation takes 3-5 days. For polyaspartic-based systems, installation can be completed faster with quicker return to service.

Yes. Properly installed quartz broadcast flooring meets requirements for USDA and FDA-regulated food processing facilities. The seamless, non-porous surface is easy to sanitize.

With proper installation and maintenance, quartz broadcast flooring can last 15-20+ years in commercial environments.

Yes, with UV-stable topcoats. Quartz systems work great for exterior walkways, patios, and breezeways. For pool areas, see our pool deck coatings.

For residential garage floors, flake epoxy systems are typically better—more cost-effective and excellent for typical garage use. Quartz is designed for heavy commercial environments.

Not sure if quartz broadcast is the right fit for your space? Call (847) 999-6330 - we’ll recommend the best system for your needs.

© Copyright Concrete Shield Coatings Inc, all rights reserved. | Terms Of Use | Privacy Policy