What Is Epoxy Floor Coating?

Finding the Perfect Balance with Our Epoxy - Flake System

Epoxy is a two-part resin system that bonds to prepared concrete and cures into a hard, seamless surface. It’s a popular choice for homeowners and businesses who want a floor that’s easy to clean, resistant to stains and chemicals, and looks dramatically better than bare concrete.

Where Epoxy Coatings Work Best

Epoxy is often the best fit when you want a strong balance of performance + value, especially in:

- Garages used for parking, storage, home gyms, or workshops

- Basements where you want a sealed surface that’s easier to keep clean and can help resist everyday moisture and spills

- Commercial and light-industrial interiors like back-of-house areas, utility rooms, and workspaces where you want a clean, professional finish

If you’re comparing options, see our concrete coating systems page for a quick overview of what works best for different spaces across Chicagoland.

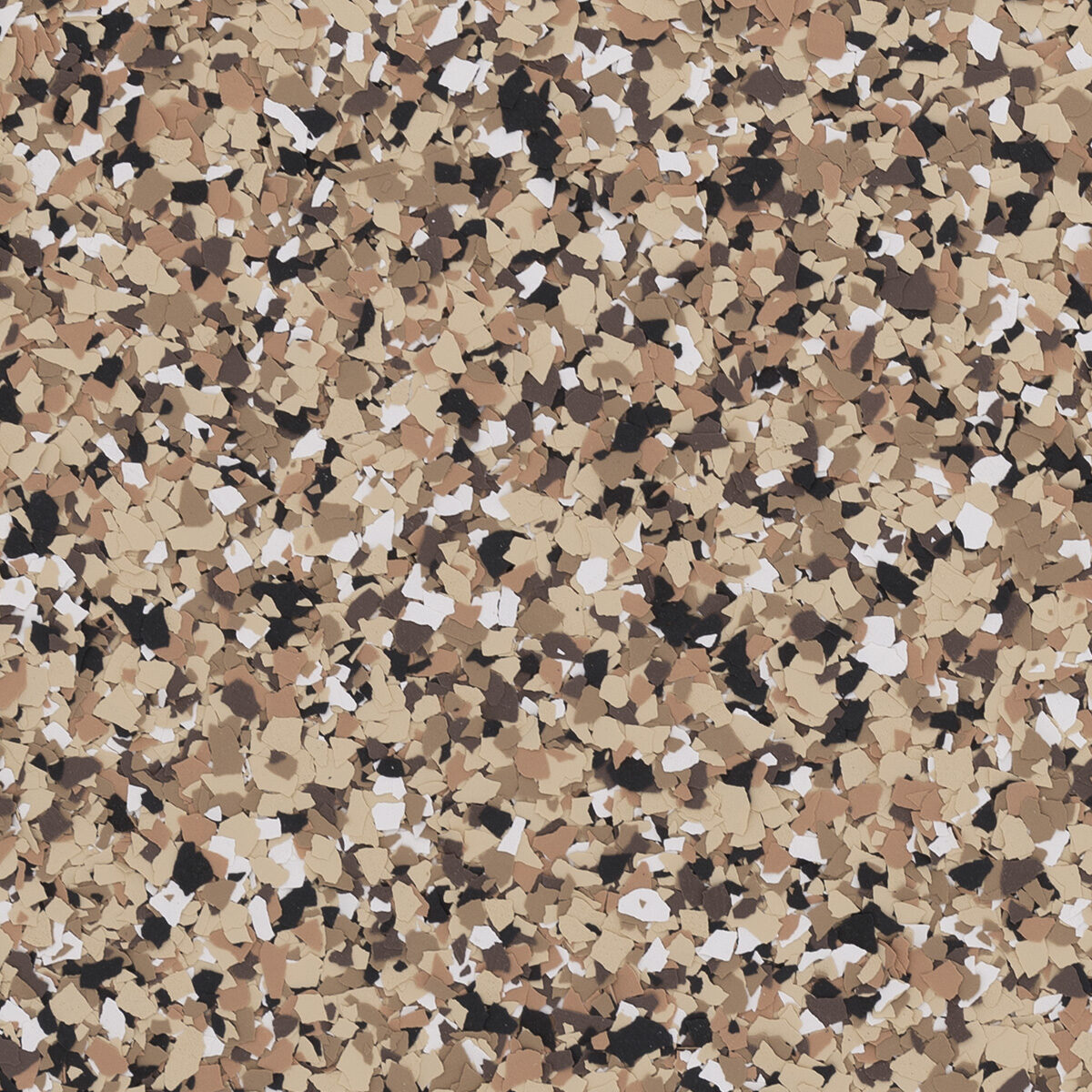

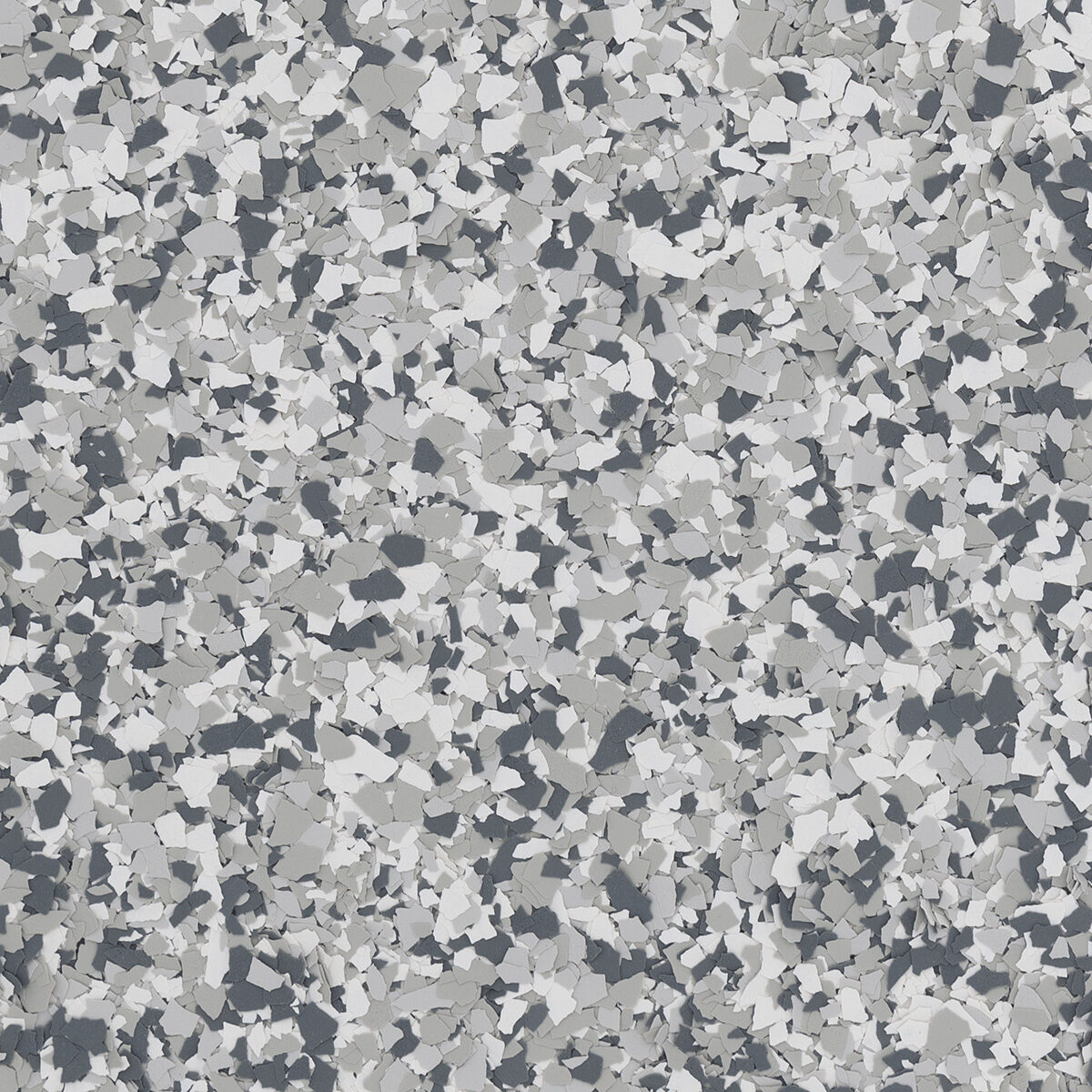

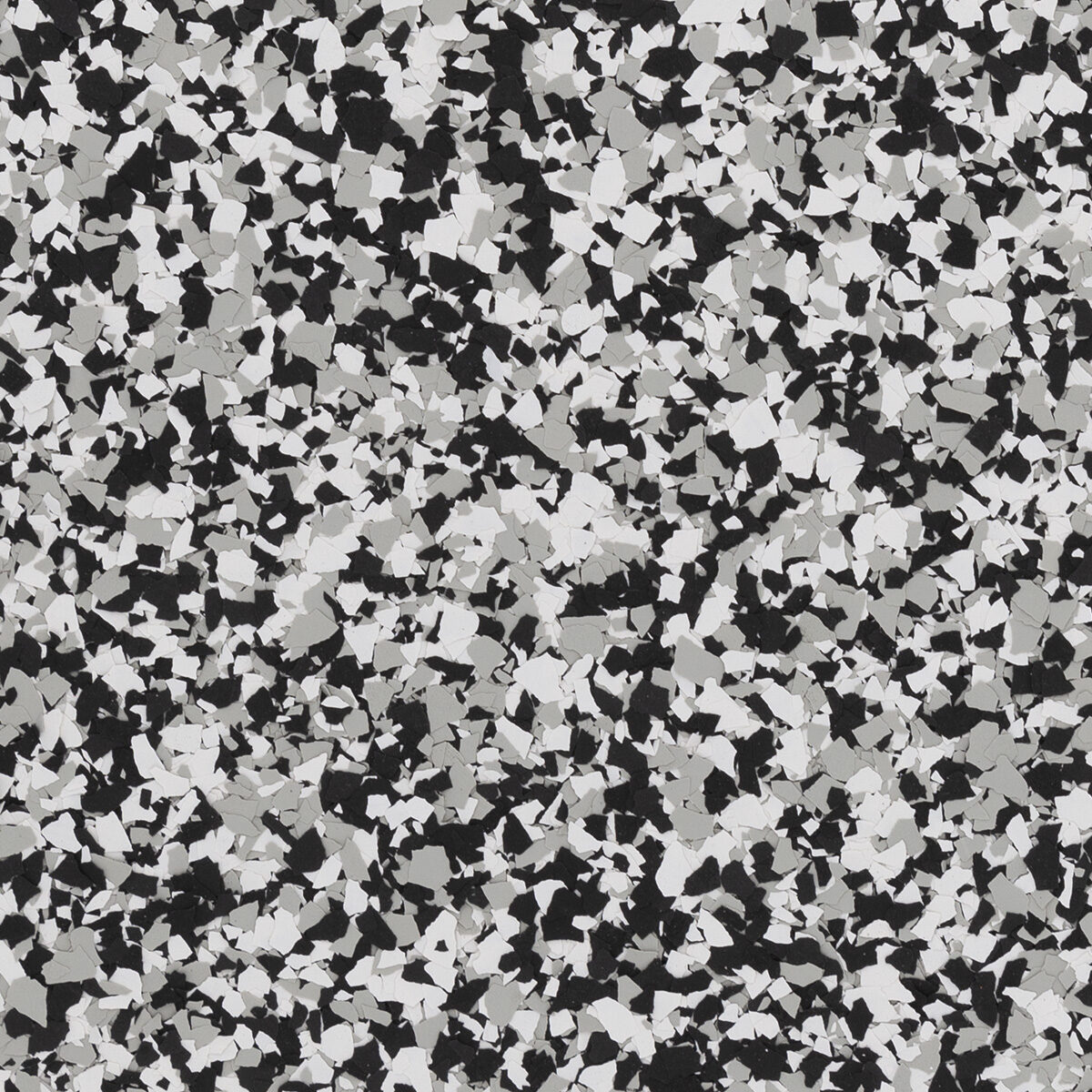

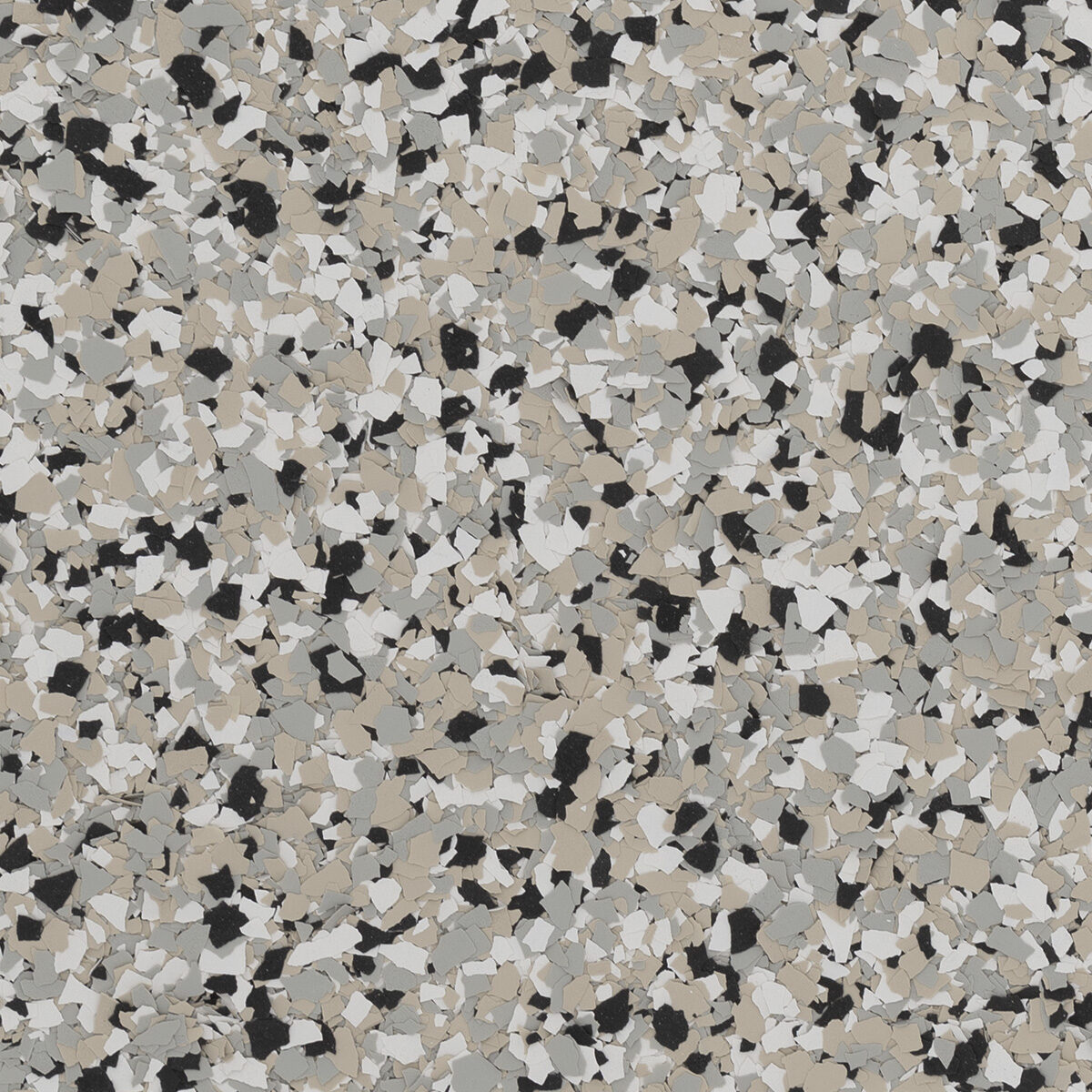

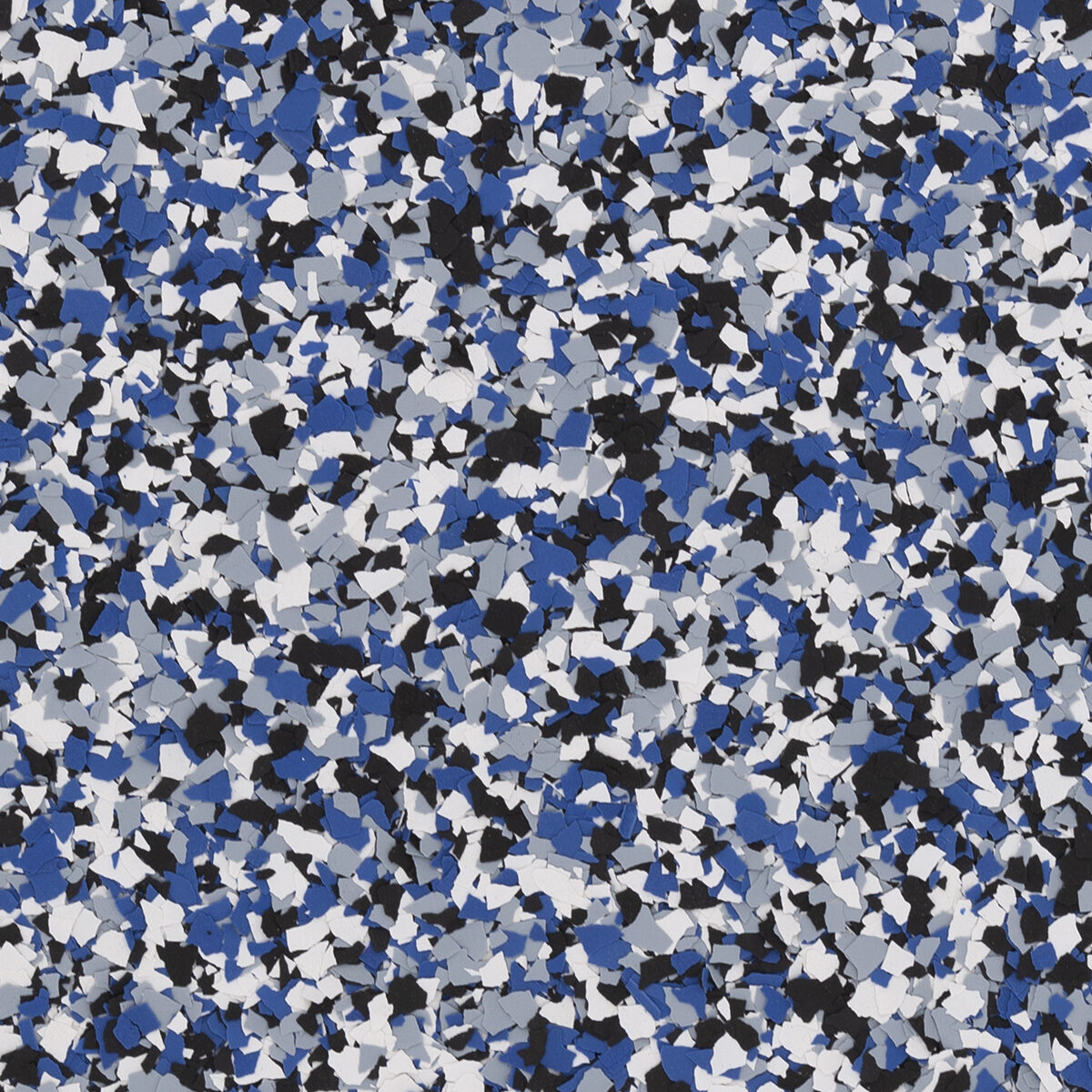

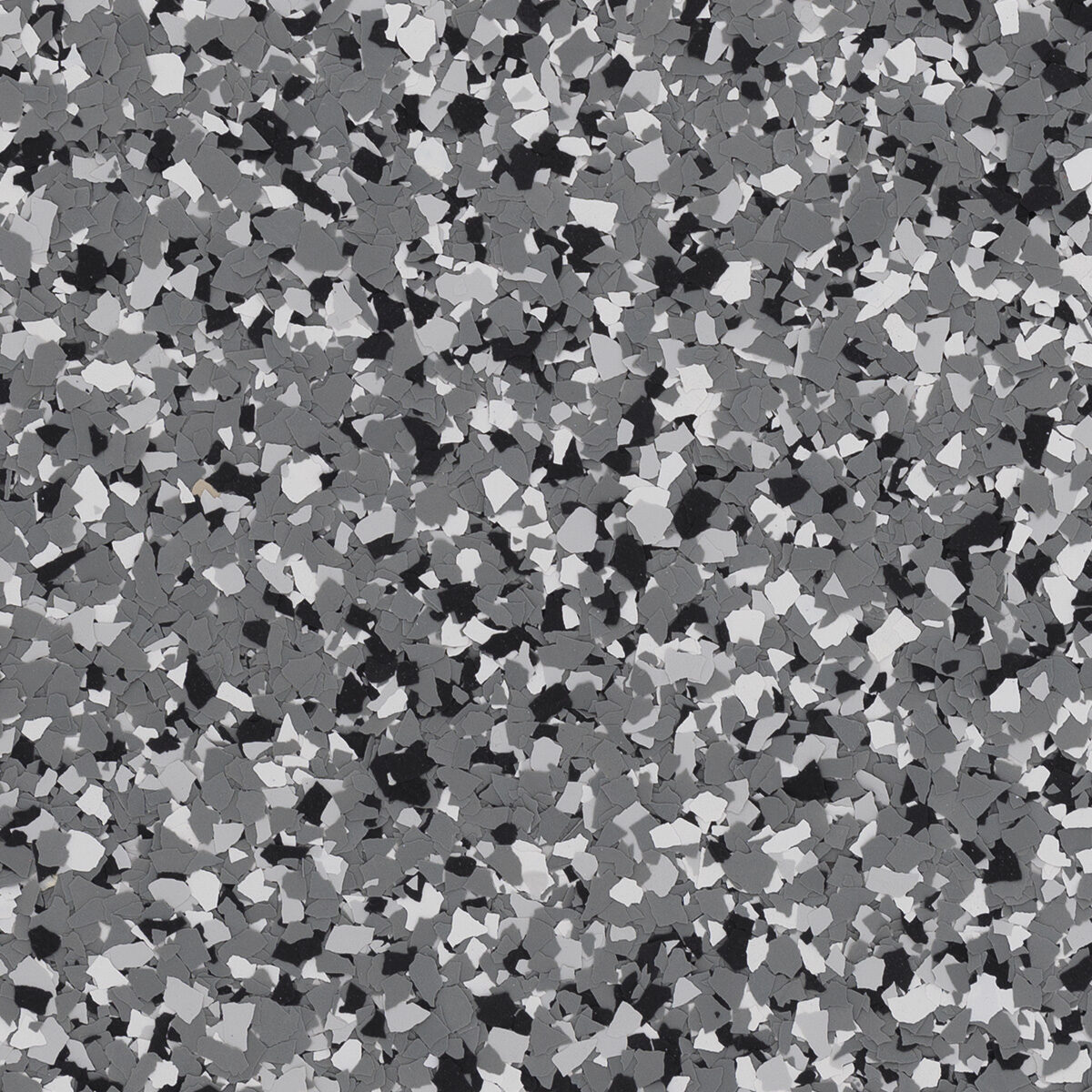

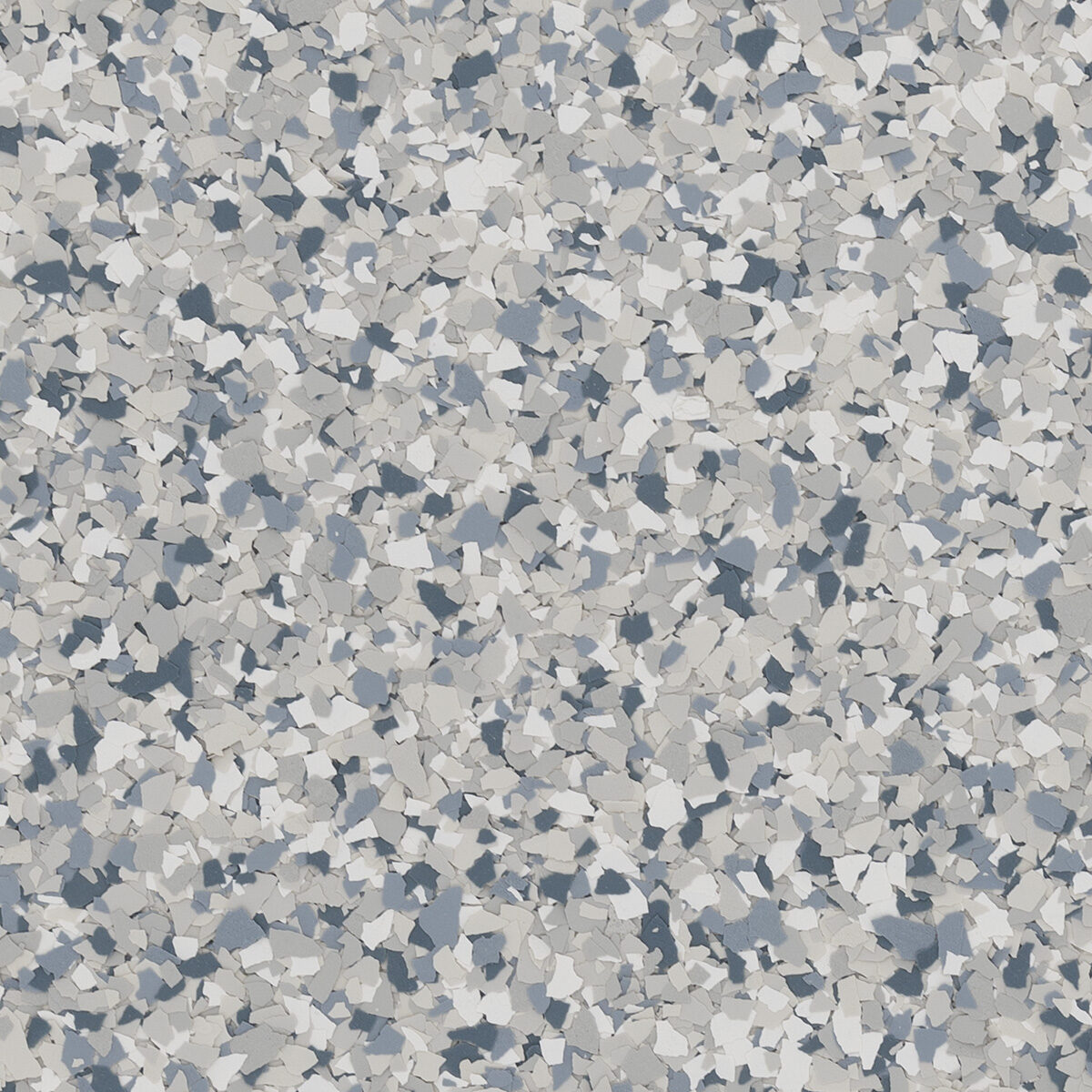

Popular Flake Colors

Choose from over 100 decorative flake color combinations. Here are some of our most popular options:

Outback

Gravel

Domino

Cabin Fever

Orbit

Wombat

Thyme

Tidalwave

Want a more custom, high-end look for a showroom-style space? Take a look at our metallic epoxy system.

Solid Color Epoxy Concrete Coatings

Long-lasting and Durable Protection

Solid epoxy concrete coating is a tough, long-lasting way to protect your concrete and make it look better at the same time. It’s made from a two-part epoxy that bonds to the floor and cures into a hard, protective finish - helping resist stains, chemicals, scuffs, and everyday wear.

It’s a great fit for all kinds of spaces, from garages and basements to warehouses, retail stores, restaurants, schools, and hospitals. Want something more specific? We can also customize the look and performance so the finished floor matches how you’ll actually use the space.

Check out these popular solid epoxy colors! But don't worry, we have plenty more options to match your unique home or business style.

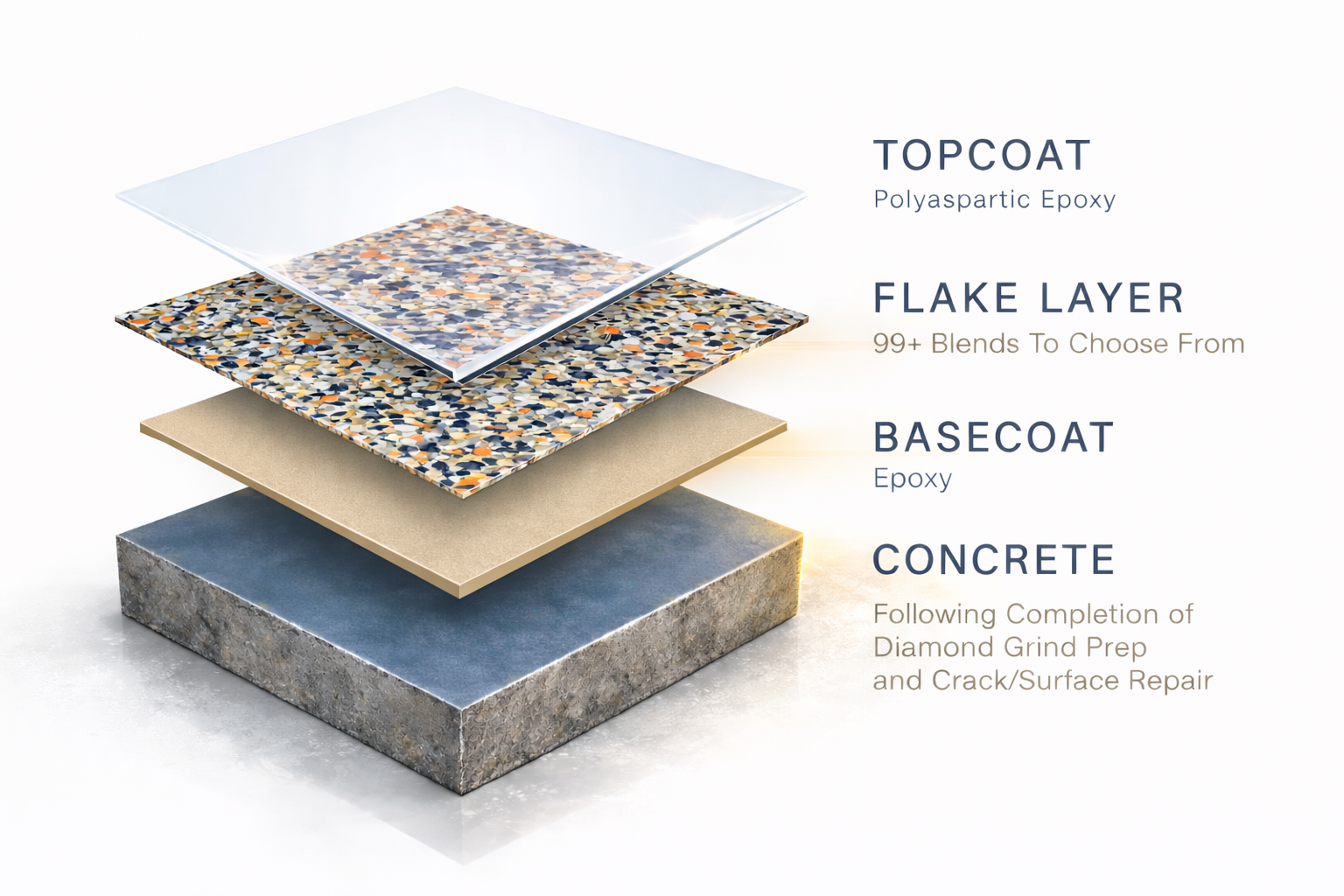

Our Epoxy Floor Installation Process (What Makes It Last)

A long-lasting epoxy floor starts before the epoxy ever goes down. Here’s what to expect when we install an epoxy system:

- On-site evaluation (concrete condition, moisture, how you use the space, and your design goals)

- Concrete prep with professional grinding and repair work to create the bond profile epoxy needs

- Base coat / build coat (system-specific for performance)

- Decorative layer (flake broadcast or solid color)

- Topcoat to lock in the finish and boost durability

- Final walkthrough with care instructions and curing expectations

Timeline: When Can I Walk or Park on an Epoxy Floor?

In most cases, you’ll be able to start using your garage again in about 1 to 2 days after installation. That usually means:

- Day 1: Concrete prep + base coat installation + full flake broadcast

- Day 2: Remove excess flakes, scrape/vacuum the floor, then apply the topcoat

- Day 3: Light use is typically okay, and parking is usually fine for most homeowners

Epoxy Floor Coating FAQ (Chicago Area)

Quick, straight answers to the most common questions homeowners and businesses ask before choosing an epoxy floor system. If you don’t see your question, call us — we’re happy to help.

Tip: The best epoxy floor results come down to surface prep, the right system for your space, and a durable topcoat.

Most professional epoxy garage floor projects in the Chicago area fall into a range because every slab is different. Pricing depends on square footage, concrete condition (cracks/oil stains), how much grinding/repair is needed, and whether you choose a multi-layer flake system or a simpler solid color.

The fastest way to get an accurate number is an on-site evaluation — we’ll look at your concrete, talk through how you use the space, and quote the right system (not a one-size-fits-all template).

In most cases, our epoxy flake systems are completed over two working days:

- Day 1: Concrete prep + base coat + full flake broadcast

- Day 2: Remove excess flakes, scrape/vacuum, then apply the topcoat

Most homeowners can start using the garage again shortly after that — and we’ll give you clear “walk/park” guidance based on your conditions (temperature, humidity, and the specific system installed).

Lifespan depends on surface prep, coating quality, and how the space is used. A professionally installed epoxy floor can be a long-term upgrade when installed on properly prepared concrete and protected with a durable topcoat.

To get the most life out of your floor, the two big levers are: (1) correct prep (grinding + repairs + moisture checks), and (2) basic maintenance (keeping grit and winter salt from acting like sandpaper).

Epoxy is a true resin system designed to bond to prepared concrete and cure into a hard, protective surface — it’s not just “paint with a shine.” That’s why epoxy is chosen for garages and workspaces where people want real chemical/stain resistance and a floor that’s easy to clean.

The key is prep: epoxy needs clean, profiled concrete to bond correctly. Skipping grinding, ignoring contamination, or trapping moisture are the most common reasons coatings peel or fail early.

Usually, yes — as long as the concrete is properly prepared first. That typically means mechanical grinding, targeted repairs for cracks/pits, and cleaning/removing contamination (like oils or old coatings) so the epoxy can bond.

If there are deeper issues (like ongoing moisture coming through the slab), we’ll flag that during the evaluation and recommend the right next step before coating.

A high-gloss surface can be slick when water is present — especially in garages where rain or snow melt gets tracked in. The good news is you can add traction without making the floor look “rough.”

Common solutions include a full flake broadcast (adds texture and hides dirt well) and/or a slip-resistant additive in the topcoat. During your estimate, we’ll recommend the right traction level for your household and how you use the space.

Yes — epoxy is often a great basement-floor upgrade because it creates a sealed, easier-to-clean surface that holds up well to everyday life (spills, storage, laundry-room mess, and general wear).

If your basement has active water intrusion, that should be addressed first. For basement-specific options, see Basement Floors.

Keep it simple: sweep/shop-vac grit regularly, then wet-clean as needed with a gentle cleaner and warm water. The biggest Chicago-specific tip is not letting winter road salt sit on the floor — remove it promptly so it doesn’t grind into the topcoat.

Floor mats near entry points (and where tires sit) can also cut down on salt, grit, and moisture wear.

Get Started Today

Interested? Click HERE to request a quote or call us at 1(847) 999-6330. We look forward to exceeding your expectations.

Residential Coating Options

© Copyright Concrete Shield Coatings Inc, all rights reserved. | Terms Of Use | Privacy Policy